BDX BatchMatic™ Fertigation System

Batch Fertigator | Simple Operation | Multi-Zone

Description

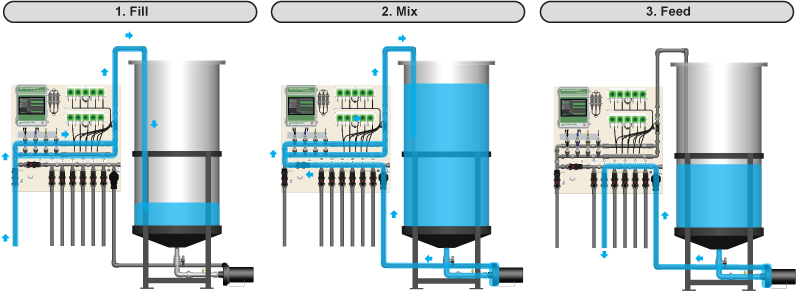

BDX BatchMATIC™ Fertigation System is a nutrient mixing and irrigation system for batch mixing and distribution to plants, hydroponic systems or holding tanks. The machine works in a simple fill-mix-feed sequence that is easy to program and run.

The base system has six (6) 'zone' valves expandable up to fourteen (14) total irrigation zones or batch tanks per machine. Available with 5, 6, 10 or 12 chemical pumps for EC nutrient dosing, pH up, pH down, and ORP as required. Precision sensors and rugged pumps offer reliable and accurate control. Built with FDA compliant tubing, the dosing pumps inject chemicals quickly and precisely.

The controller's large built-in color touch screen display provides an easy to use interface for monitoring the sensor readings and configuring the dosing settings. Display includes features such as:

- Current batch status, recipe, stage, etc.

- Pause, continue, skip & run-now features for manual control

- Sensor / system monitoring & display

- Schedule event configuration

- Recipe editing and creation

- Alarm settings and configuration

- Email account & recipient settings

- Guided sensor calibration screens

- Manual pump priming and system diagnostics

- User accounts & login screen

These pre-assembled panels come ready to dose! Just mount, plug in power and plumb the water connections!

Customer must supply a mixing tank and install the level sensors in the tank/plumbing.

Built on over a decade of proven technology and components with new, enhanced capabilities to meet the growing demand for highly reliable autonomous dosing applications. Designed to meet the needs of typical multi-room indoor growing facilities and mid-sized greenhouses without being over priced or over-complicated.

Motorized Ball Valves

The BDX's rugged, motor-operated PVC ball valves are designed and assembled in the USA for demanding agricultural applications. Ball valves are high-reliability and self-cleaning for low-maintenance. High-torque Italian-made actuator from one of the largest actuator manufacturers in the world features a large motor and very strong, heavy steel gearing. Manual override knob allows operation even in the event of a power failure. Tested to well over 100,000 cycles, BV series valves combine high-quality components for reliability that your crop can depend on.

Batch Dosing Advantages

Batch dosing is a simple method for pre-mixing a batch of nutrient water then feeding it to crop zones or holding tanks once the mixture is complete. Most hydroponic nutrients have instructions for feeding in ml/gal which is what the BDX BatchMatic™ system uses for creating a recipe. Setting up recipes is as simple as entering the information from the manufacturer's feeding schedule making the system straight forward to setup and understand.

Batch dosing is typically considered the safest approach to fertigation as it allows all parameters to be checked prior to sending the mixture to plants. Any critical problems, such as chemical outages, equipment faults, etc. can be detected before any damage is done to crops.

BDX BatchMatic systems have a variety of safety functions and alarm capabilities including:

- Batch checking for maximum deviation

- Dual sensor maximum differential monitoring

- pH failure to correct

- pH dosing in wrong direction

- pH auto-recorrect

- Failure to fill tank

- Tank over-filled

- Main pump failure

- Component failure (dosing pump, sensors, valve driver, etc.)

The system can automatically pause when any error condition is encountered and send an email alert to multiple recipients, as well as display a red alert dialog on the touch screen indicating the error.

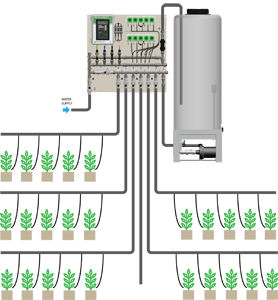

Direct Feeding

BDX systems can feed directly to crop zones with drippers, etc. Direct fertigation is ideal for applications requiring 1-2 feedings per day.

Stock Holding Tanks

BDX systems can manage up to 10 holding tanks with individual recipes. A low-level sensor in each holding tank triggers the BDX system to mix a new batch of the specified recipe to re-fill the low tank. Irrigation from the holding tanks is managed by a GrowControl™ GCX system or other irrigation management controller. This arrangement is ideal for feeding many zones or where irrigation scheduling requires frequent cycles across many zones.

BDX System Includes

- BDX Dosing Panel, Pre-Assembled

- 1/2HP 22GPM Recirculation/Irrigation Pump

- RX1 Outlet Relay for Circulation Pump

- 2x SXL High/Low Mix Tank Sensors

- High Speed 480ml/min Peristaltic Chemical Pumps

Batch mixing tank not included.

Redundant Sensor Option

Precision, rugged sensor probes are made in USA. Available with redundant sensors for enhanced protection from sensor failure. Automatically shut-down the system when error between sensors exceeds allowed limits and trigger alarms.

-20 - 60°C

0-14 pH

0-5000 uS (0-2500ppm)

+/-1000mV

Valve Expansion Panel

Eight (8) valve expansion panel allows up to 13/14 zones to be managed by a single BDX dosing system. Easy connection to base system with manifold connection and wall mounted panel.

Input Trigger Module

Input trigger module is equipped with eight (8) inputs to expand the two (2) internal BDX machine's trigger inputs. Up to two (2) DXI8 modules can be added for a total of 18 inputs on the BDX system. Inputs can be used with low level sensors to trigger batches to refill holding tanks, monitor for chemical outages, or for external machine stops from over-fill sensors or push-button stations.

Documents & Media

Agrowtek Inc.

3365 Gateway Rd

Brookfield, WI 53045

Phone: (847) 380-3009

Fax: (224) 538-2320

sales@agrowtek.com